RFID

From Logistics to Storefront. Precision, Speed, and Attention to Detail.

RFID is an automatic data recognition system that is based on wireless communication between IC tags and readers/writers, and allows the real-time capture of information by reading multiple tags at once.

TOKYO YOSHIOKA provides a system for real-time information sharing based on RFID to help optimize production, inventory, and sales, and to streamline and improve efficiency.

Receiving,

warehousing, picking, shipping, returns, inventory operation efficiency, inventory accuracy, inspection accuracy, and search efficiency are all improved, and overall logistics productivity also increases.

To stores.

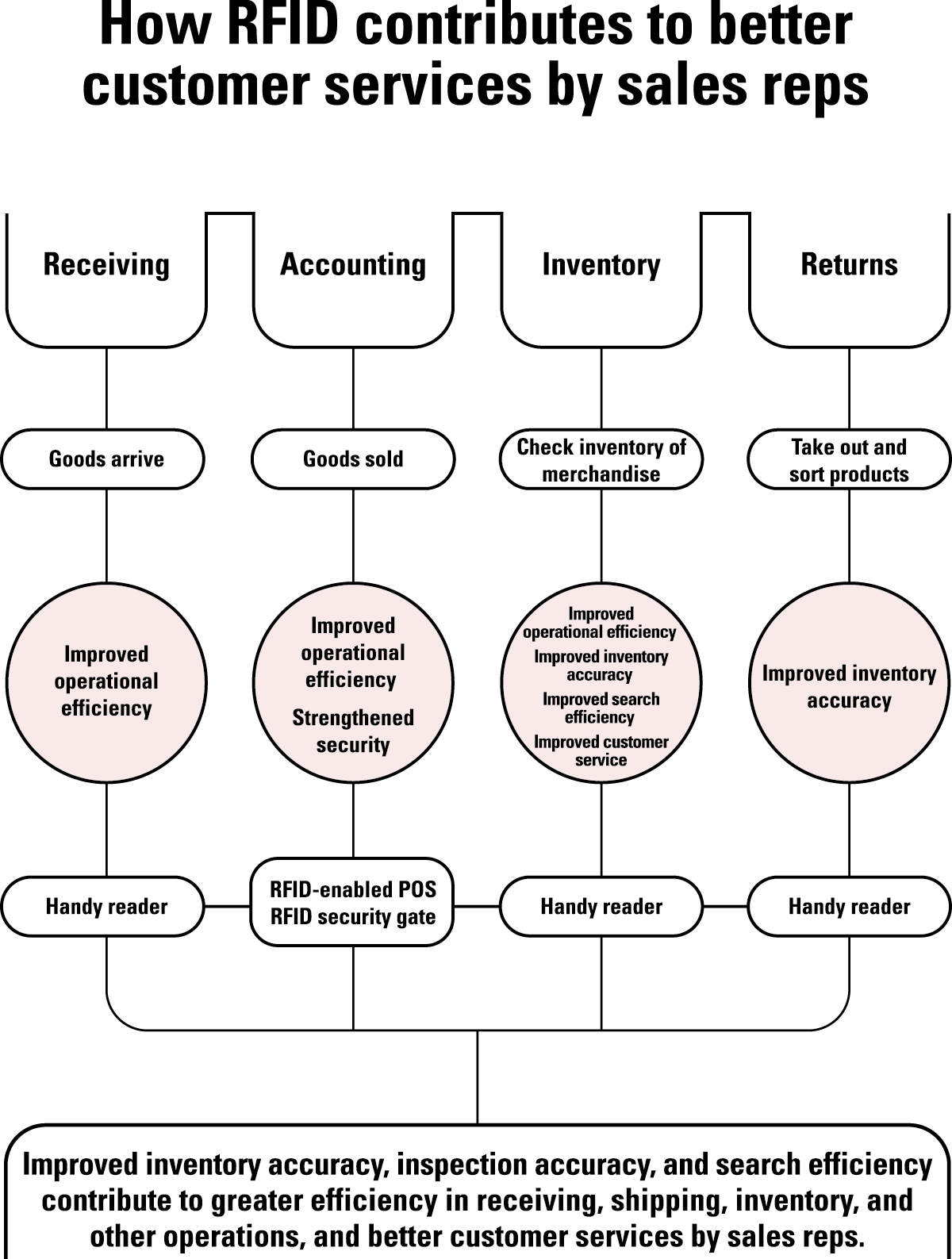

Receiving, accounting, shipping, inventory operation efficiency, inventory accuracy, inspection accuracy, and search efficiency are all improved and security is strengthened, contributing to better customer services by sales reps.

Precision, Speed, and Attention to Detail.

TOKYO YOSHIOKA provides a system for real-time information sharing based on RFID to help optimize production, inventory, and sales, and to streamline and improve efficiency.

Improved efficiency in logistics warehouses

- Receiving/shipping inspection

- Collective reading with RFID gate antennas

- Reduces inspection time and supports large-volume receiving and shipping.

- Reduces workload of workers and realizes a comfortable workplace.

- Picking

- Significantly reduces workload by eliminating the need to search for tags in locations that are difficult to see.

- Eliminates the need to scan tags one by one, saving hours of effort significantly.

Improved efficiency in stores

- Receiving goods into stores (incoming goods inspection)

- Reduced time for incoming goods inspection

- Reduces the workload of sales staff, creating a more comfortable workplace

- Faster product display, fewer missed sales due to stock-outs

- Improved inventory system

- Stockroom and storefront location management

- Optimized product display and reduction of missed sales

- Reduction of unnecessary inventory

- Improved inventory system

TOYO YOSHIOKA’s Three Commitments to RFID

- 01

Commitment to

qualityUse of world-class inlay makers

Optimal process control by the latest precision machinery and engineers - 02

Commitment to

the best priceInventory of several types of standard inlays

In-house printing and encoding facilities in Tokyo and Shanghai - 03

Commitment to

customer satisfactionFlexible response, from small to large lots, by using a variety of printing and encoding machines